The places where mining machinery and engineering machinery are active are mostly mining sites in mountainous areas and desert areas that are far away from ordinary human life. Sometimes they even work 2,000 meters underground. There are many types of such machinery, from mineral crushing machinery to cutting machinery, screening machinery, loading machinery, conveying machinery, etc., all of which are equipment that operates continuously 24 hours a day. If any of these machines breaks down, it will have a great impact on production at the mining site. Moreover, the recent increase in the size of machines has made maintenance work very difficult.

Therefore, in terms of the environment in which bearings are used, there are many conditions that are very harsh on bearings, such as "heavy load + impact load", "light load + high-speed rotation", "heavy load + low-speed rotation", etc. Therefore, users desire bearings that are robust, durable and highly reliable that can withstand these harsh working conditions. In order to meet these needs of users, we have been integrating material technology, lubrication technology, analytical technology and more advanced bearing design technology to contribute to customers improving production efficiency and reducing maintenance costs at mining sites in harsh environments.

The places where mining machinery and engineering machinery are active are mostly mining sites in mountainous areas and desert areas that are far away from ordinary human life. Sometimes they even work 2,000 meters underground. There are many types of suc

More

Excavator vehicle axle systems adopt different structural designs due to different application conditions. Locomotives and buses have axle boxes. The bearings are connected to the bogie through the axle box, and the bearings are connected to the bogie sid

More

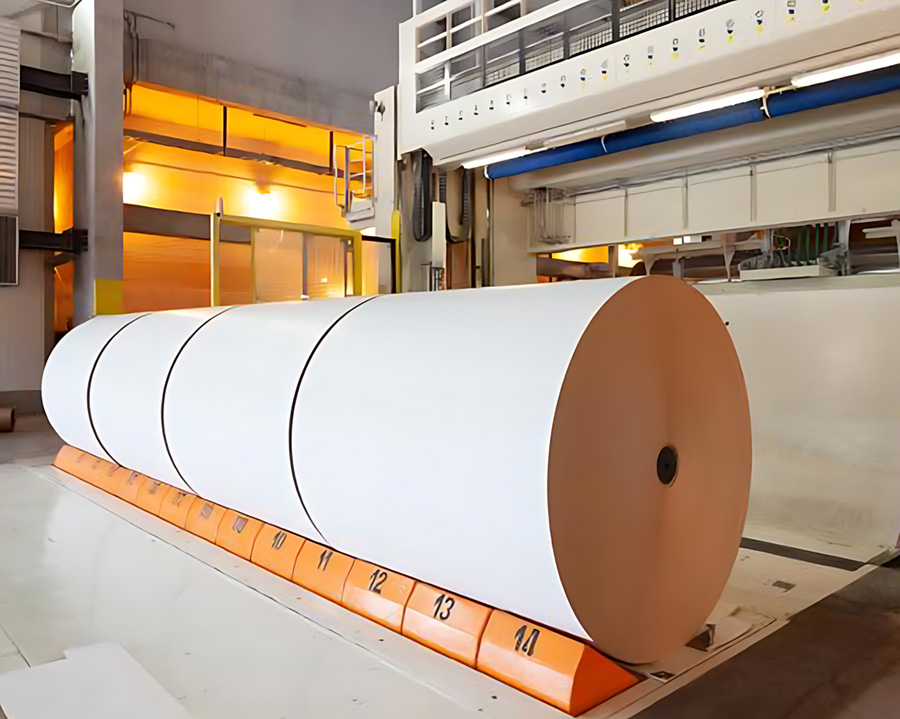

Pulp and paper bearings Meeting the needs of a challenging industry Market forces and increasingly stringent regulatory requirements make it more difficult than ever for pulp, paper and paper converting operations to be profitable. Competition is fierce a

More

There are many types of aircraft bearings. In response to customer demands for reduced weight, reduced environmental pollution and high performance from bearings, bearing systems have become more complex and require greater reliability and quality control

More